2 min read

SAP S/4HANA Roadmap: A Definitive Guide for Business Transformation

In today's fiercely competitive global market, we should recognise the indispensable role of dynamic and robust...

By: Ross Barnes-Moore on Sep 13, 2022 2:19:32 PM

A new feature in S/4HANA is the ability to level production capacity for both discrete and process manufacturing.

This allows you to adjust the order load for a work center. By planning and scheduling order dispatches to fit warehouse time slots, inventory levels are better managed and the production process runs more efficiently.

Production Capacity Leveling ensures warehouse orders are timed to deliver what you need when you need it by viewing your real-time data for existing inventory, capacity, and materials and delivering at a time slot that best fits your production requirements.

Having a better handle on your production orders helps to combat overproduction (which is one of Toyota’s seven types of waste) and underproduction. Planning, scheduling, and execution allow you to optimize resources by leveling production to have a more consistent output and therefore reduce overproduction.

Imagine a technology product line. You have the capacity to produce 112 laptops per week with 16 being made every day. If 100 product orders were waiting or being built, capacity leveling states you should add the remaining 12 to the list of existing production orders.

Following this approach, the number of open orders will always be level with the available capacity. This means that when delays occur fewer production orders will be released, similarly if demand were to increase production orders will increase along with it.

The benefits of Production Capacity Leveling are its contribution to a reduction in manufacturing cycle time and days in inventory as well as an improvement in on-time delivery performance.

Manufacturing cycle time is reduced by instantly adapting production schedules to current warehouse conditions. Days in inventory are reduced by having a real-time view of inventory and product data and on-time delivery performance is improved by a quicker response to new demands and adapting to warehouse conditions.

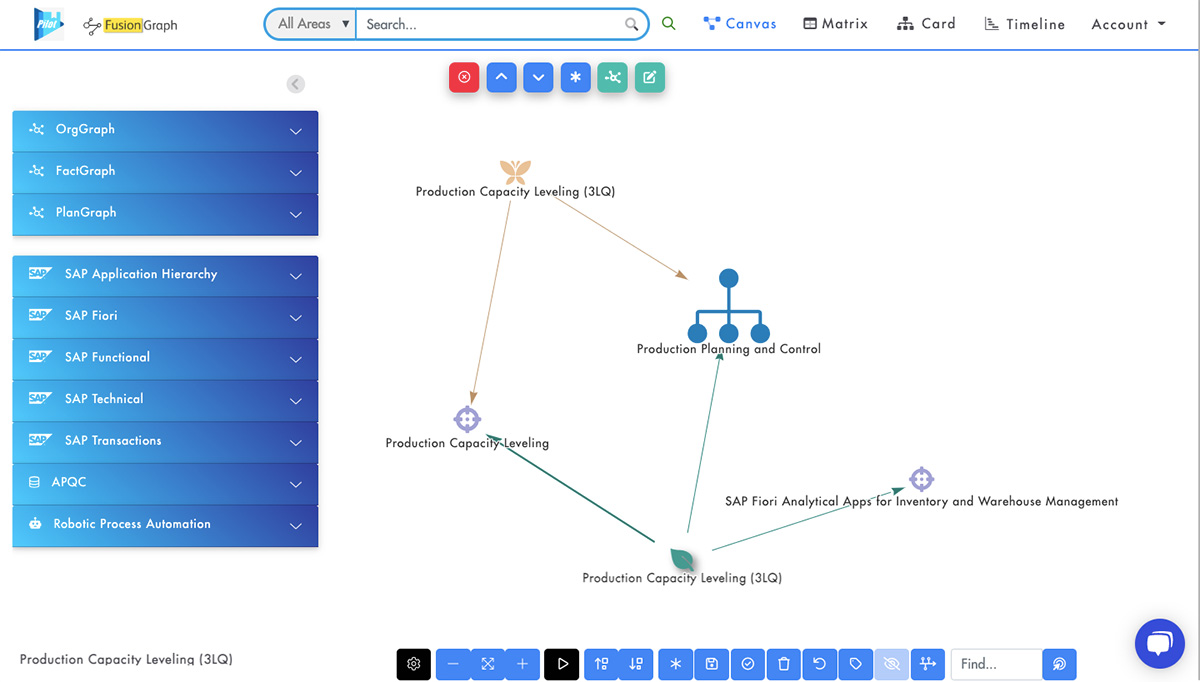

We discovered this new SAP PP functionality using FusionGraph - the visual EPR roadmapping tool. Find out how you can discover new S/4 functionality to support your business case by booking a FusionGraph demo here.

Jul 14, 2023by Tom Brown

In today's fiercely competitive global market, we should recognise the indispensable role of dynamic and robust...

Jul 13, 2023by Ross Barnes-Moore

A graphical BOM is a tree-like structure that shows the components or raw materials required to produce a product. It...

Jun 7, 2023by Ross Barnes-Moore

Enhanced Scheduling in SAP S/4 HANA is a module that provides advanced scheduling capabilities for organisations that...