A multi-level BOM is a hierarchical structure that shows the components or raw materials required to produce a product at multiple levels of assembly. For example, a train may have a multi-level BOM that includes subassemblies such as the engine, transmission, and chassis, which are then assembled into the final product.

A multi-level routing, on the other hand, shows the sequence of operations required to produce a product at multiple levels of assembly. It includes the work centers where each operation takes place, the machines or tools needed for each operation, and the personnel required to perform the operations.

A multi-level routing enables you to see the sequence of operations required to produce a subassembly and the dependencies between them, as well as the operations required to produce the final product.

In SAP S/4 HANA, you can create and manage multi-level BOMs and routings using the Material Master and the Production Order transactions. These tools enable you to plan and manage your production processes more effectively, ensuring that you have the materials, personnel, and equipment you need to produce high-quality products on time and within budget.

Key Features of Multi-Level BOM and Routing in SAP S/4 HANA

- Some of the key features of Multi-Level BOM and Routing in SAP S/4 HANA include:

Hierarchical structure: Multi-level BOMs and routings have a hierarchical structure that shows the components or operations required at each level of assembly.

- Real-time updates: Any changes made to the BOM, or routing are immediately reflected in the system, ensuring that everyone has access to the latest information.

- Version management: You can maintain multiple versions of the BOM and routing, enabling you to track changes and maintain an audit trail.

- Integration with other modules: Multi-level BOMs and routings are integrated with other SAP modules, such as production planning, materials management, and quality management, enabling you to plan and manage your production processes more effectively.

- Material availability check: You can check the availability of materials required for production at each level of assembly directly from the BOM, helping you to avoid delays and minimise production downtime.

- Simulations: You can simulate the production process at each level of assembly using the routing, enabling you to identify bottlenecks, optimise the process, and reduce costs.

- Scalability: Multi-level BOMs and routings can handle complex product structures and manufacturing processes that involve multiple levels of subassemblies and operations, making them suitable for large-scale production environments.

What benefits does Multi-Level BOM and Routing in SAP S/4 HANA provide to your organisation?

- Improved visibility and understanding: Multi-level BOMs and routings provide a clear and detailed view of complex product structures and manufacturing processes, making it easier to understand and manage.

- Better planning and coordination: Multi-level BOMs and routings enable better planning and coordination of production processes at multiple levels of assembly, leading to improved efficiency and reduced costs.

- Enhanced version control: By maintaining multiple versions of the BOM and routing, you can easily track changes, maintain an audit trail, and ensure that everyone has access to the latest information.

- Improved material availability management: Multi-level BOMs enable you to check the availability of materials required for production at each level of assembly directly from the system, helping you to avoid delays and minimise production downtime.

- Better simulation and optimisation: You can simulate the production process at each level of assembly using the routing, enabling you to identify bottlenecks, optimise the process, and reduce costs.

- Improved collaboration: Multi-level BOMs and routings enable better collaboration between different departments, such as engineering, production, and quality control, helping to streamline processes and improve overall efficiency.

- Greater accuracy and consistency: By using a standardised format for BOMs and routings, you can ensure greater accuracy and consistency in your production processes.

- Better control of inventory and material requirements: Multi-level BOMs enable better control of inventory and material requirements for each level of assembly, reducing waste and improving overall efficiency.

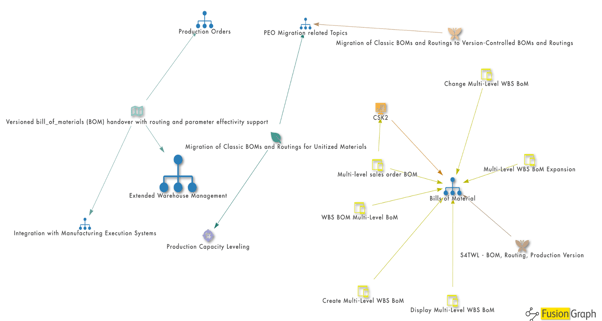

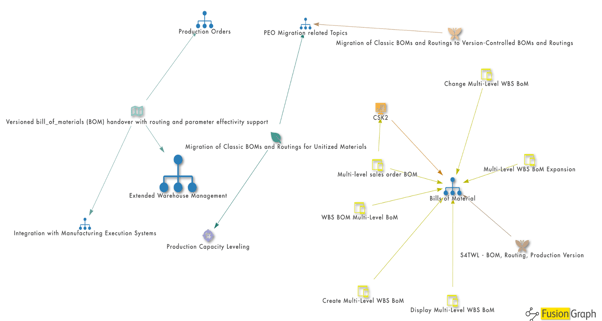

With the help of FusionGraph it's easy to discover and understand new functionality like this and add it to your business case for S/4HANA migration.

Click the link the request a demo.

.png)